Views: 0 Author: Site Editor Publish Time: 2025-07-02 Origin: Site

When it comes to selecting the ideal material for industrial components, especially in air-handling equipment, ADC12 aluminum alloy and stainless steel are two of the most commonly evaluated options. Both materials offer distinct mechanical properties, corrosion resistance, and heat endurance. However, their application suitability varies greatly depending on operational requirements.

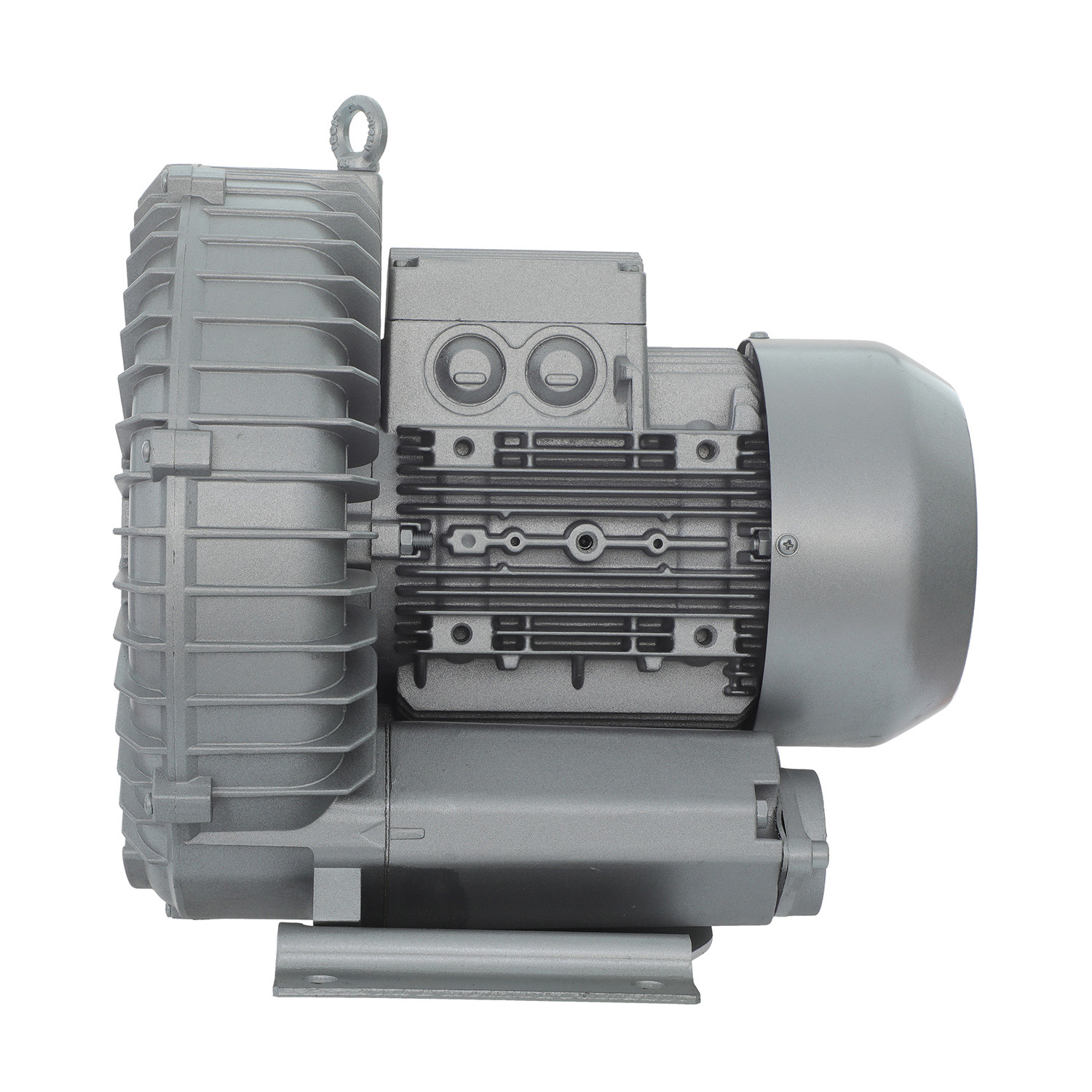

(Aluminum Blower)

ADC12 aluminum alloy, a popular die-casting material, is a high-silicon-content aluminum alloy that offers good castability, excellent thermal conductivity, and decent corrosion resistance. It is widely used in automotive parts, compressor components, and various industrial blower housings due to its lightweight nature and ease of molding.

Stainless steel, on the other hand, is an iron-based alloy containing chromium, which gives it its remarkable corrosion resistance. It is often used in applications requiring high strength, oxidation resistance, and long-term durability under harsh conditions.

ADC12 performs adequately in moderate-temperature environments, typically withstanding temperatures up to 200°C before significant degradation in mechanical properties. While it has good thermal conductivity, making it ideal for heat dissipation in equipment, prolonged exposure to high temperatures can lead to softening and fatigue failure over time.

Stainless steel far outperforms ADC12 in terms of thermal resistance. Depending on the grade (e.g., 304 or 316), stainless steel can maintain its structural integrity at temperatures well above 500°C, making it the go-to choice for high-heat or flame-exposed applications. Furthermore, stainless steel retains its tensile strength and hardness even in elevated thermal environments, adding to its reputation for longevity and reliability.

Without question, stainless steel exhibits superior heat resistance, making it suitable for high-temperature operations. However, this performance comes with increased weight and cost.

In the context of air-moving equipment such as side channel blowers, centrifugal fans, and ducted systems, weight matters—both in terms of design and energy efficiency. ADC12 aluminum alloy is significantly lighter than stainless steel, offering a better power-to-weight ratio for dynamic parts like impellers and fan blades. This advantage translates into lower energy consumption and easier installation.

Stainless steel offers higher corrosion resistance, particularly in aggressive or acidic environments. However, for general industrial air-blowing applications—which are typically dry or mildly humid—ADC12’s corrosion resistance is sufficient, especially when coated or anodized.

ADC12 is also easier to cast and machine, reducing overall production time and cost. Stainless steel, while stronger, requires more intensive machining and forming techniques, adding to the overall manufacturing expense. If your project demands tight tolerances and quick turnaround, ADC12 is the more practical option.

Because of its lighter mass and casting-friendly properties, ADC12 also exhibits better vibration absorption when properly designed. Stainless steel components tend to resonate more, which may affect noise levels in blower applications.

Though stainless steel requires less maintenance in corrosive environments, ADC12 components are easily replaceable and cost-effective, allowing for cheaper and faster servicing. Moreover, if the blower is not exposed to extreme thermal or chemical stress, ADC12 can offer a lifespan that meets or exceeds application expectations.

For air delivery systems, particularly in standard industrial, HVAC, or clean-room settings, ADC12 aluminum alloy offers the best balance of performance, cost-efficiency, weight, and manufacturability. Its lightness, castability, and adequate thermal and corrosion resistance make it ideally suited for components like blower housings, impellers, and ducts where stainless steel might be overkill.

Both ADC12 and stainless steel are recyclable. However, ADC12’s production has a smaller carbon footprint, especially when recycled aluminum is used. This makes it a more environmentally responsible choice for large-scale manufacturing.

Stainless steel grades such as 304 and 316 are non-magnetic, which is an advantage in medical or precision electronic environments. ADC12, being a non-ferrous aluminum alloy, is also non-magnetic, but lighter and easier to work with in such sensitive applications.

While stainless steel is often chosen for its polished appearance and surface hardness, ADC12 can be anodized or painted to match industrial or aesthetic requirements. This flexibility allows for more creative design options without compromising on structural performance.

In summary, ADC12 aluminum alloy and stainless steel each have their strengths. Stainless steel excels in high-temperature resistance and aggressive corrosion conditions, making it a strong candidate for chemical plants or outdoor marine environments. However, for most air-handling applications, especially industrial blowers, ADC12 aluminum alloy stands out due to its lightweight construction, cost-effectiveness, sufficient thermal performance, and ease of manufacturing.

ADC12 is the more suitable and efficient material choice. It delivers excellent performance where needed while keeping costs, weight, and energy use low.

Choosing the right material isn’t about picking the strongest or most expensive—it’s about choosing the right balance of properties for your specific application. And when it comes to blower equipment, ADC12 aluminum alloy offers that perfect balance.