Views: 0 Author: Site Editor Publish Time: 2025-10-18 Origin: Site

In industrial environments where side channel blowers operate, noise reduction becomes a crucial consideration. While these blowers are highly efficient in providing clean, oil-free air for applications like aeration, vacuum lifting, and pneumatic conveying, they tend to generate noticeable noise during high-speed operation. This is where an acoustic enclosure—a purpose-built soundproof housing—plays an essential role in maintaining workplace comfort, equipment protection, and compliance with noise regulations.

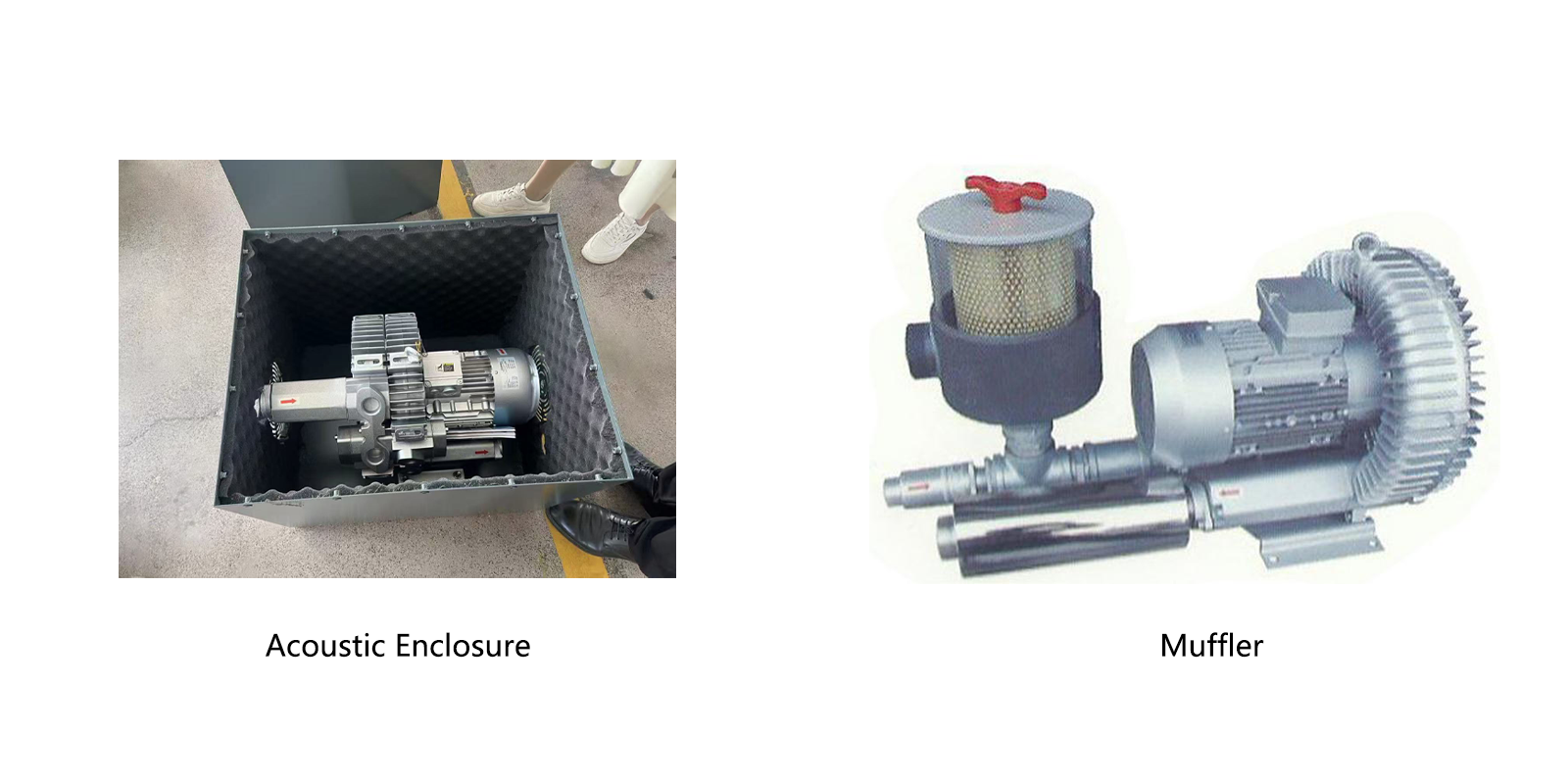

An acoustic enclosure is a specially designed box or cabinet that surrounds a side channel blower to significantly reduce the noise it produces during operation. Constructed from sound-absorbing materials such as perforated steel, acoustic foam, and mineral wool insulation, the enclosure isolates and minimizes noise transmission without affecting the blower’s performance.

These enclosures are engineered to manage both airflow and heat dissipation, ensuring that the blower continues to operate efficiently while remaining quiet. Many models feature ventilation systems, cooling fans, and air inlets/outlets to maintain proper temperature balance.

In essence, an acoustic enclosure provides a quiet operating environment without compromising the blower’s functionality or lifespan.

The primary reason for using an acoustic enclosure is to minimize noise levels generated by side channel blowers. Depending on the model and size, blowers can produce noise levels up to 80–100 dB(A), which is uncomfortable and potentially harmful in continuous operation environments. An acoustic enclosure can reduce noise by 10–25 dB(A), creating a safer and more pleasant workspace.

In industries such as food processing, wastewater treatment, packaging, and printing, regulatory bodies often enforce strict occupational noise limits. Installing an acoustic enclosure helps businesses stay within permissible sound exposure levels, ensuring compliance with ISO, OSHA, or local noise standards.

Reducing blower noise enhances employee concentration and communication in the workplace. A quieter environment not only prevents hearing fatigue but also promotes greater operational efficiency and safety awareness.

Beyond noise control, acoustic enclosures provide physical protection for blowers. They shield the unit from dust, moisture, and accidental impacts, which can extend the blower’s lifespan and reduce maintenance costs. Some models are equipped with weatherproof coatings for outdoor installations.

While both mufflers and acoustic enclosures aim to reduce blower noise, their designs, effectiveness, and applications differ significantly.

A muffler, also known as a silencer, is typically attached to the inlet or outlet of the blower. It reduces the airflow noise caused by turbulence and vibration in the air path. Mufflers are compact, lightweight, and cost-effective, making them suitable for mild noise reduction requirements.

An acoustic enclosure, in contrast, surrounds the entire blower. It addresses not only airflow noise but also mechanical and motor noise. Its comprehensive coverage provides a much greater reduction in overall sound levels compared to a muffler alone.

Mufflers generally offer a noise reduction of about 5–10 dB(A), while acoustic enclosures can achieve 15–25 dB(A) or more, depending on material and design. For facilities with strict noise restrictions, an acoustic enclosure is the more effective choice.

Since acoustic enclosures completely cover the blower, they are designed with cooling vents, acoustic baffles, and air channels to prevent overheating. Mufflers, however, do not affect the blower’s heat dissipation since they only connect to air paths.

Muffler: Suitable for standard installations where moderate noise control is needed, such as small workshops or enclosed machinery rooms.

Acoustic Enclosure: Ideal for noise-sensitive environments like laboratories, production floors, hospitals, or areas close to residential zones.

In summary, mufflers reduce airflow noise, while acoustic enclosures reduce total system noise. In many cases, both are used together to achieve optimal noise control.

High-quality enclosures use multi-layered composite walls made from steel panels, foam insulation, and vibration-damping layers. These materials work together to absorb, block, and dissipate sound waves efficiently.

Since blowers generate heat during continuous operation, the enclosure integrates ventilation ducts with acoustic linings and low-noise fans. These ensure proper air circulation while preventing temperature buildup.

Modern acoustic enclosures are designed with removable panels or hinged doors for easy access. This allows operators to inspect, clean, and maintain the blower without completely disassembling the housing.

Manufacturers often offer custom acoustic enclosures tailored to specific blower sizes and installation layouts. Custom options may include stainless-steel finishes, weatherproof seals, or corrosion-resistant coatings for demanding industrial environments.

You should consider installing an acoustic enclosure in the following scenarios:

The blower is located near occupied areas or sensitive workplaces.

Noise levels exceed permissible decibel limits for your facility.

The installation site has limited space for open ventilation, increasing sound reflection.

There is a need for long-term, 24-hour operation where worker comfort is a priority.

The environment requires clean, dust-protected housing for sensitive equipment.

For example, in wastewater treatment plants, multiple blowers operate continuously for aeration. Here, enclosures significantly reduce environmental noise while keeping the blowers safe from moisture. In food or pharmaceutical manufacturing, they maintain hygiene standards by minimizing dust and debris contact.

The acoustic enclosure for a side channel blower is not just an accessory—it is a practical investment in performance, safety, and environmental compliance. While a muffler may suffice for basic noise control, an acoustic enclosure provides a comprehensive solution that tackles all sources of blower noise, offering a quieter, cleaner, and more efficient workspace.

Whether you operate in industrial manufacturing, water treatment, or laboratory applications, incorporating an acoustic enclosure ensures your operations remain compliant, sustainable, and worker-friendly. By investing in proper noise control solutions, you not only protect your equipment but also safeguard the health and productivity of your team—an essential step toward a truly efficient facility.